HOME / THERMAL POWER

ProSIM @ IPS 2025, Raipur, 13-15 Feb, 2025 orgnaised by NTPC

ProSIM was invited to exhibit and present capabilities at Techno Galaxy of IPS

2025 conference organised by NTPC. This conference was a part of

celebrations 50 years of NTPC operations.

ProSIM has been engaged with NTPC for structural integrity assessment,

remaining life assessment and life extension (RLA/RLE); and fitness for service

assessment (FFS) of its assets. ProSIM has provided services several dozens of

NTPC plants for critical piping and turbine parts. ProSIM is provider of detailed

engineering service, finite element analysis service, remaining life assessment

and extension service (RLA/RLE), fitness for service (FFS) evaluation, pipe stress

analysis service, and so on.

NTPC is transforming from a coal and gas based thermal power company to a

total energy company encompasing solar, wind, hydel, storage, nuclear and so

on with current revenues of Rs 1.81 lakh crores ( ~ US $ 21 billion). NTPC will

soon become a global energy behemoth. In this context discussions and

presentations of ProSIM as a high end engineering and R&D service provider for

energy sector was very timely.

Several senior executives of NTPC and engineers from several stations visited ProSIM stall, and discussed about ProSIM offerings. Visitors included Mr K S Sundaram, Project Director, Mr Prasenjit Pal, Executive Director, NTPC Nuclear, Mr A P Samal, GM, NTPC Nuclear, Mr Ajay Sharma, Head, Engineering, Mr A K Das, AGM, R&D, NTPC-NETRA, Mr Nagesh CGM Engineering and others.

From left to right: Mr AP Samal, GM NTPC Nuclear, Mr Prasenjit Pal, Executive Director, NTPC Nuclear with Dr Shamasundar of ProSIM @ ProSIM stall in IPS 2025.

Dr Shamasundar, MD of ProSIM explaining the Remaining Life Assessment and Extension strategy for critical pipelines of power plants. Figure shows the failure of pipeline in occasional load cases with stress exceeding 277% of the allowable stress limit. ProSIM has provided engineering solutions to increase life to desired / expected levels.

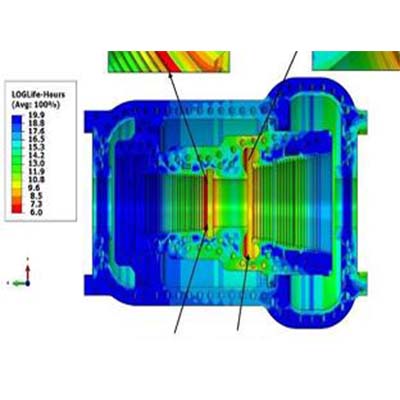

ProSIM presented capabilities for 3D Laser Scanning to create 3D CAD models of legacy assets, concuct finite element analysis, to carry out detailed RLA/RLE strategy for turbine components.