Structural Integrity Assessment of Assets

ProSIM assists asset energy asset owners and operators with its structural integrity evaluation service and help in managing the assets efficiently and enhancing the productivity of assets.

Structural integrity analysis service at ProSIM includes fitness for service evaluation, remaining life assessment service(RLA Service), remaining life extension service, and providing engineering judgments on retire, replace, repair decisions.

Structural Integrity analysis service at ProSIM is based on finite element analysis to determine the allowable stresses as per codes and standards such as API 579, ASME B&PV etc. ProSIM is a fitness for service company providing remnant life assessment services.

ProSIM project managers and team leads have worked as fitness for service consultants and remaining life assessment (RLA) consultants providing services such as fitness for service level-3,FFS Level-3 oil and gas, FFS level-3 power plant, FFS level-3 piping, FFS level-3 static equipment, remaining life assessment of service piping.

ProSIM has master service agreements with several companies to provide FFS level-3 services as per API 579 (fitness for service level-3 API 579). Remaining life assessment service of power plant piping including critical high pressure high temperature pipings. RLA service piping is based on inspection data, finite element analysis, code assessment (API 579, ASME B&PV B31.3/ B31.2 etc).ProSIM is a leader in RLA services for piping of power plants and oil and gas.

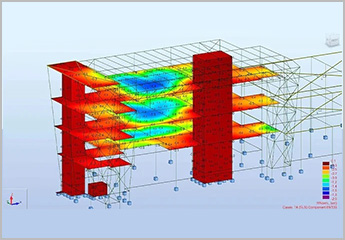

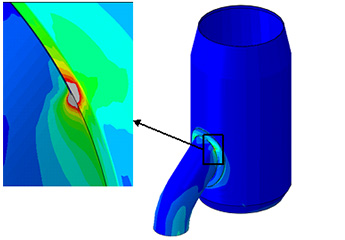

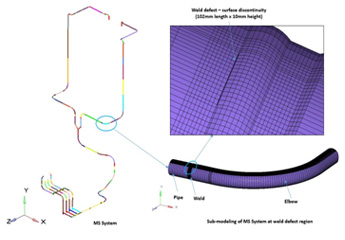

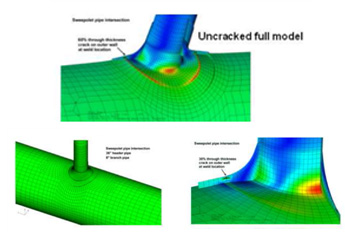

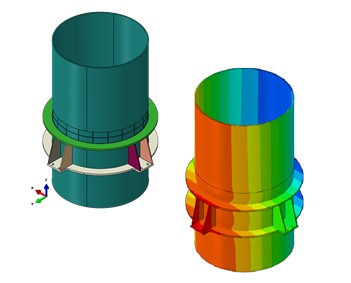

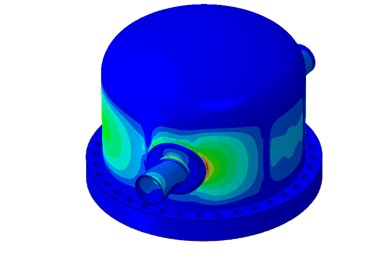

ProSIM offers expert engineering and consultancy services for structural integrity assessment of assets including energy sector (nuclear power plants, thermal power plants, oil and gas, off-shore), processing plants, and heavy equipment and machinery. Using its expertise in materials and damage modeling including fatigue, creep, creep-fatigue interaction, and crack growth; knowledge of industry specific codes such as IS, ASME B&PV, API, DNVGL, etc. and skills in computational techniques such as non-linear finite element analysis (FEA), computational fluid dynamics (CFD), multi-physics simulations; and using our experience, we provide services to study the structural integrity of assets, and conduct fitness for service studies (FFS); remaining life assessment/ extension (RLA/RLE services), engineering critical analysis (ECA) and provide repair, reuse, retire judgements. Our abilities to conclusively calculate the strength and stiffness of asset sections studying the effects of corrosion, erosion, pitting, conducting accurate finite element analysis calculations under different load cases s defined by the codes. We specialize in using sub-modeling approach in finite element analysis (to combine 1D pipe elements to 3D elements).

We assist our customers to have safe and reliable operations, mitigate risks, enhance uptime, reduce downtime, and assist them for overall productivity increase of their asset utilization.

Increasingly, we are assisting our customers in implementation of IIoT, Cloud, AI/ML based digital twin development.

Weld integrity assessment using FEA

Using submideling approach – interlinking of 1D pipeElement -3D FE elements for remaining life assessment Of Main Steam Pipes in a thermal power Plant

Fatigue Crack Growth analysis with rate dependent plasticity modeling in a High temperature piping segment

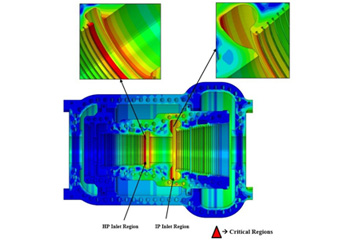

Remaining life assessment (RLA/RLE) studies of a turbine casing.

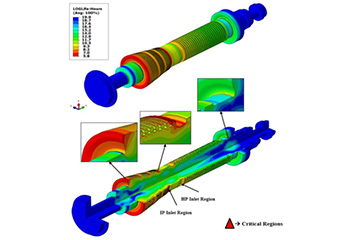

Creep-fatigue interaction studies using finite element analysis (FEA) of a turbine rotor shaft.

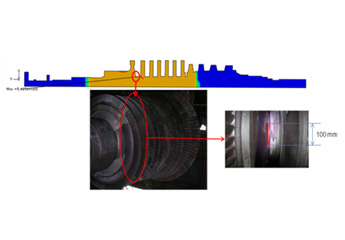

Creep Fatigue Damage sizing using finite element analysis (FEA) Compared with measurement during inspection.

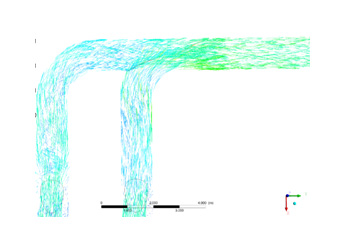

Fluid Structure Interaction (FSI) studies to determine Air curtain degradation in a blower.

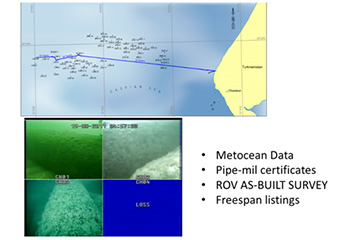

Offshore pipeline integrity assessment

Structural Integrity Check for Piping Systems

fitness for service evaluation for tanks

Sequence of activities for conducting ECA of an underground pipeline.

1. Pipeline Study

- Pipeline Geometry and Material: Diameter, wall thickness, grade, age, type, specified material properties (yield andtensile strength, toughness)&pipeline design code

- Pipeline operational characteristics: Operating pressure andtemperature, temperature and pressure cycles

- Type of product carried by the pipeline and pipeline environments (internal and external)

- Details of Corrosion protection

- History of the pipeline (from manufacturing and constructionthrough to operation)

- Past history of failures and repairment/ replacements done.

- Intended future operating conditions.

2. Considerations for stresses on the pipelines

- Loads acting on the length of the pipeline containing a defect.

- If these loads will change in future

- Considerations of circumstances that may result in overpressure (e.g. surged. Are

- Cyclic loads on the pipeline

- Failure stress

3. Review of Inspection Method used

- Type of inspection methods used – MFL/ UT and any other surveys.

- Minimum sizing threshold and what are the sizing tolerances and accuracies of the inspection methods.

4. Review of Defects identified during ILI (in-Line inspection)

- Cause for the identified defects (due to bacterial growth, corrosion, fluid constituents etc.)

- Dimensions of the defects reported (length, width, depth, acuity,profile)

- Types of defect (metal-loss, dent, gouge, girth weld defect,crack, laminations, blister)

- Potential for defect growth

5. Location Overview

- Location accuracies (depending upon agency, and pigging equipment); determine dig verification location;

6. Anomalies assessment Overview

- Level 1 assessment will be carried out for all the identified anomalies considering failure stress, acceptable safety factor and FCA

- If level 1 assessment shows unacceptable anomalies, these defects will be identified as inputs for dig verification and additional NDE

- The identified defect locations will be superimposed on the actual pipeline map for providing locations for dig verification

- Level 2 assessment will be carried out based on the dig verification and additional NDE’s

7. Identifying potential for SCC by considering the following

- The operating stress exceeds 60%of the SMYS

- The operating temperature hashistorically exceeded 38ºC

- Pipeline segment is less than or equalto 32 km downstream from acompressorstation

- Age and coating type

- Initial identification of candidate sites foradditional indirect surveys and subsequent directexaminations (if required)

8. Identifying consequences for the anomalies

- Consequences of failure for identified defects will be correlated with pipeline location class (population density) and risk-based inspection or time-based approach will be considered for mitigations.

- Expected failure mode (running fracture, leak, rupture)

9. Integrity Assessment

- Predict degradation mode and rate of degradation

- Predictive Models – Operational data

- Historical inspection data

- Future degradation rates

- Determine Remnant life

- Corrosion tolerance and degradation rate

10. Rating the pipeline for MAOP (maximum allowable operating pressure) based on

- Allowable design pressure of the weakest element considering the worst defect remaining in the pipeline

- Maximum safe pressure to which a pipeline should be subjected.

- Consideration of connected lines

11. Future inspection/ remedial actions &recommendations

- External corrosion

- Coating rehabilitation

- CP performance

- Internal corrosion

- Operational mitigation – inhibition, batching, dew point etc

- External welded sleeves

- Sectional replacement – interim temporary repair – clamps, welded sleeves etc