Structural Integrity Assessment of Material Handling Equipment for Nuclear Power Plants: Seismic qualification of cranes.

ProSIM works as FEA seismic consultants to provide seismic analysis service to manufacturers of variety of cranes. We specialize in the seismic qualification of various crane types, including electric overhead traveling cranes, gantry cranes, manual cranes, electric hoists, and underslung cranes. These cranes are subjected to numerous loads such as dead weight, safe working load, horizontal loads, wind loads, and seismic loads in the form of Operating Basis Earthquake (OBE) and Safe Shutdown Earthquake (SSE).

As seismic analysis consultants, ProSIM has provided seismic qualification services to several crane manufacturers supplying MHEs to nuclear power plants (NPPs). Our seismic evaluation process adheres to IS 807 standards and involves comprehensive checks on all crane components, including girders, end carriages, trolleys, platforms, and hoists. Using finite element analysis (FEA), we ensure that each component meets stringent seismic qualification criteria as defined in codes and standards, as well as guidelines by operators and regulators. We use floor response spectra (FRS), typically provided by the operator, for specific plant site and elevation. The cranes are subjected to different load combinations along with seismic load combination. The calculated stresses are compared with allowable stresses per IS code to qualify various crane components. We also conduct limiting deflection qualifications, assessments of bolts, welds, wheels, and bearings.

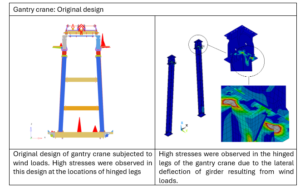

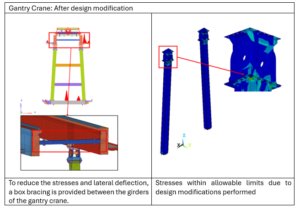

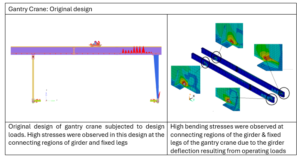

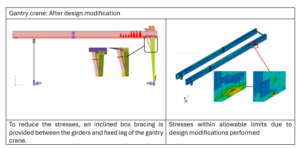

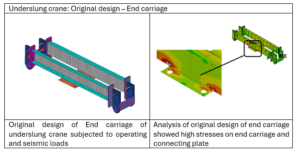

Often, manufacturers of cranes consider only static loads in the design calculations. This results in failure to qualify as per nuclear seismic codes. One of the significant challenges is initial failure of cranes to meet seismic qualification, requiring design modifications and re-analysis, for optimisation of the crane. To address this issue, ProSIM performs design calculation based on mechanics, using dynamic seismic loads. In addition to these measures, we implement local design modifications to ensure the cranes meet seismic qualification criteria as per ASME nuclear codes.

Another challenge is the time taken for bolt and weld qualification and the subsequent reporting. To streamline this, we have developed in-house applications that automate the design, qualification and reporting processes for bolts and welds. This has significantly reduced time and errors, enhancing the reliability of the qualification process.

Through meticulous structural integrity evaluation and seismic analysis, we ensure that all crane components, including bolts and weld connections, comply with the necessary standards and qualify for operation in nuclear power plant sites.

ProSIM submitted a comprehensive seismic qualification document to NPP operators such NPCIL, confirming that all cranes meet safety standards and are operationally ready for seismic zones. By overcoming challenges and implementing innovative solutions, ProSIM ensures the structural integrity and reliability of cranes in nuclear power plant.