Seismic qualification of fuel oil piping of EDG of nuclear power plant

ProSIM is an expert company providing nuclear seismic analysis. As seismic analysis consultants, ProSIM provides nuclear seismic analysis services. ProSIM has supported several EPCs, system integrators of global nuclear ecosystem as FEA seismic consultants and provided FEA seismic qualification services.

ProSIM worked as seismic design consultant and seismic analysis consultant to a EPC contractor tasked with setting up emergency DG (EDG) in a nuclear power plant. As a part of seismic analysis service, ProSIM carried out Dynamic pipe stress analysis of fuel oil system piping in the EDG system for seismic qualification.

Comprehensive piping engineering service at ProSIM includes piping design service, Piping modelling service, and pipe stress analysis service.

As piping design consultant, ProSIM provided the Basic engineering service including design calculations for Pipe sizing, Pressure drop calculation, Preparation of piping layout, Qualification of pipeline, supports, components for their operating conditions, applicable occasional loads, nuclear safety class, seismic category & codes and standards to be used for analysis. The fuel oil system belongs to Safety class 3 & Seismic category 1. As a pipe stress analysis consultants, ProSIM qualified pipelines for different occasional loads like Operating Basis Earthquake (OBE), Safe shut down Earthquake (SSE) & Air shock wave (ASW) analysis.

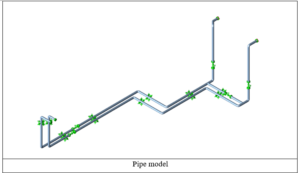

Pipe Modeling is done using CEASAR II including the mass details of line mounted equipment, valves, etc. Individual loads & Load combinations: Identify and quantify all potential loads acting on the system, including static loads (such as weight of the pipes and fluid contents), thermal loads (due to temperature changes), and Dynamic pipe stress analysis (such as pressure surges from pump starts or stops), Occasional loads (OBE, SSE, ASW) & their combination as per ASME Codes/ AERB guidelines. CEASAR pipe stress analysis service is provided by ProSIM.

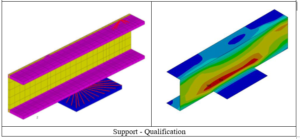

Perform Pipe stress analysis to calculate stresses, displacements, Nozzle loads at the connected equipment’s within the fuel oil piping system under various load combinations like Sustained, Operating, Expansion & Occasional are within the acceptable limits & Ensuring the Fuel oil piping meets the requirements of ASME Sec III Div 1 subsection ND. As FEA Seismic Qualification consultants, ProSIM Qualified the supports as per ASME Sec III Div 1 NF. As dynamic pipe stress analysis consultant, ProSIM assisted the EPC contractor to get the pipe stress analysis reports approved by the nuclear power plant operator, as per guidelines of regulator and assisted in seismic qualification of the entire EDG set including the piping and equipment. Seismic analysis FEA or Seismic analysis service is provided by ProSIM to qualify the Fuel oil system. seismic Qualification is also done for the supports to check its integrity.