ProSIM FEA Engineering Services Capabilities using Altair SimSolid

ProSIM is aFEA consultancy service company offeringCAE servicesand SimSolid FEA service.

Altair SimSolid can be used to perform quick evaluation of designs using meshless methods. SimSolid saves significant time in evaluation of different design scenarios in a time efficient manner by eliminating two major time consuming steps in conventional finite element analysis viz., geometry preparationand meshing. Using SimSolid ProSIM engineers perform finite element analysis including linear static, modal, thermal properties, along with more complex coupled, nonlinear, transient dynamic effects. All typical connections such as bolt/nut, bonded, welds, rivets, sliding are considered in SimSolid simulations.

ProSIM provides trained engineers to work on SimSolidasFEA outsourcing service Consultantsto work for structural analysis. ProSIM offersCAE services across many industries for rapidevaluatio design processesusing SimSolid FEA service.

ProSIM capabilities inSimSolid FEA service for rapid design evaluation underdifferent static &dynamic loadings are:

- Eliminate geometry simplification and meshing

- Quik Model preparation

- Analyze complex parts and large assemblies.

- It is tolerant of imprecise geometry, and its assembly connections are industry best at handling ragged contact surfaces

- Advanced automation workflows are built into Sim Solid to help setup large models

- Supported Connections and Boundary Conditions

- Assembly Connections: Smart auto connections, bonded, sliding, separating with friction, bolted, spot & laser welds, fillet/seam welds, bushings, adhesives and virtual connectors

-

- Loads & BC’s: Immovable constraint, sliding constraint, hinge constraint, enforced displacement, force, pressure, gravity, thermal, inertia relief, bolt/nut preload, dynamic loads, hydrostatic loads, bearing loads, and remote loads

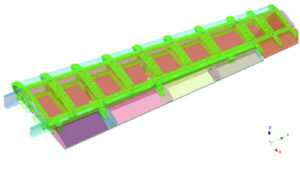

Geometry nonlinear (contact) static analysis of Frame mounting structure is carried out under SimSolid finite element analysis service.

Figure-1: Geometry contact creation for Analysis of Complex Parts & Large Assemblies

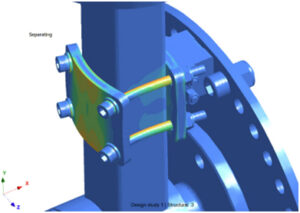

Figure-2: Nonlinear (contact) analysis accurately reproducing the contact between bolt and plate

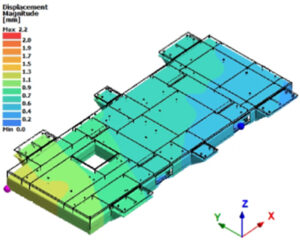

Figure-3: Static Strength Analysis of Base Frame for different loading conditions