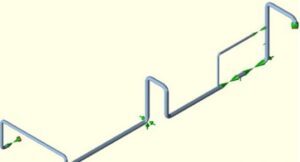

Pipe Stress Analysis of a buried uPVC & RTRP composite piping network

ProSIM works as Piping Stress Analysis consultant from Bangalore India. ProSIM has recently successfully delivered pipe stress analysis for a large irrigation piping network with uPVC & RTRP composite materials.

Pipe stress analysis has been carried out using the CAESAR II software in accordance with ISO 14692 standard.

Detailed piping layout drawings were provided by client as input. Design conditions like design pressure, operating pressure, design temperature, operating temperature, hydro test pressure, ambient temperature was considered for analysis.

Material properties like Elastic modulus, Hoop modulus, thermal coefficient of expansion, Pipe density, Fluid density etc. were considered as per Pipe Manufacturer’s data.

Soil properties like soil density, buried depth, yield displacement factor, thermal expansion coefficient, temperature change etc. were also considered for analysis.

Various load cases such as hydro case, operating case, sustained case, occasional load case, expansion case, seismic loads were considered for pipe stress analysis of Irrigation Network piping system.

Modelling a pipeline with steep slopes, irregular turns and long distances are challenging. Buried pipe was subject to large bending and tensile loads because of soil movement. Sources of soil movement include differential ground settlement, fault displacement, displacement during earthquakes, frost heave or ice thawing etc., were considered in the analysis.

Because of soil movement, buried pipes may experience significant bending and tensile loads, leading to non-qualification in sustained load cases due to inadequate thickness to withstand soil weight. We recommended increasing the pipe thickness to address this issue.

Significant seismic loads induce substantial moments in the pipeline, particularly at bends and specific locations, causing model failure. Therefore, we proposed the installation of thrust block supports and anchors to mitigate these effects. As part of piping design service, ProSIM provides engineering solutions after conducting pipe stress analysis.

We suggested thrust block supports, increase in pipe thickness, addition of air vent valve and anchor supports

Pipe Stress Analysis output reports consisting of Displacements, Restraint summary report, Stresses Extended report, Stress Summary report, Detailed Piping Layout & Generated ISO were provided to client.

ProSIM provides end-to-end piping engineering service as part of its engineering outsourcing activities including onsite engineering service and offshore engineering service.