Fitness for Service Assessment of an Autoclave Reactor Vessel

Autoclave reactor vessels are robust containers designed to withstand high pressures and temperatures while containing reactive or hazardous materials. They are commonly used in processes such as chemical synthesis, polymerization, and hydrothermal reactions. These vessels come in various designs, including cylindrical, spherical, or custom configurations, depending on the application requirements.

Fitness for service evaluation as defined in API 579, is a systematic approach used to evaluate the structural integrity of pressure vessels, including autoclave reactor vessels. Key component of fitness-for-service (FFS level-3 oil and gas) includes stress analysis by finite element method. The FFS Level-3 services from ProSIMensure compliance with industry standards and code such as ASME, Fitness for service level-3 API 579 which provide guidelines for assessing vessel integrity.

In a petrochemical manufacturing plant, an autoclave reactor vessel used for polymerization processes underwent FFS assessment due to concerns about fatigue cracking in welded joints. In the finite element analysis model of reactor vessel, transient pressure and temperature loads were considered as per the process parameters of autoclave. As part of FEA services at ProSI, analysis was carried out and checked for fatigue life of equipment for the given loading conditions as per ASME Sec VIII Div 2. FFS evaluation revealed life was shorter than the expected lifespan of the equipment at the high stress concentration near the welds, indicating a risk of crack propagation and failure.

After structural integrity assessment, modifications to the design thickness and welding type were suggested to address the identified issues. FFS level-3 assessment, serves as a valuable for structural integrity assessment and remaining life extension. This methodologies provide strategies to mitigate risk, reduce downtime and enhance productivity.

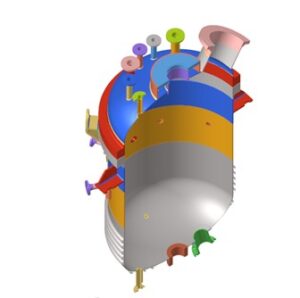

FE Model of Reactor vessel