DESIGN OPTIMISATION OF MATERIAL HANDLING EQUIPMENT

ProSIM has executed projects for Material handling equipment as an engineering design consultant. ProSIM has expertise in offshore engineering service for material handling packages for nuclear, heavy industries and maintenance sector. ProSIM works as engineering design consultants for structural evaluation of equipment such as EOT cranes, gantry cranes, manual cranes, electric hoists, trestle structures etc.

Design optimization of material handling equipment includes FEA structural validation for overall assembly of the crane design. This includes FEA simulation based for lifting loads, self-loads and seismic loads, wind loads and shock loads with load factors to qualify rope drum, crab structure, equipment mounting platforms, crab structure, LT and CT rails, anti-jump lugs, girders and end carriages. Analytical design calculations based on FEA results are performed for structure, weld, bolts, bearings etc to co-relate and analysis results. ProSIM value addition to customer is the ability to understand the failures in the design and revise design without compromising pre-existing limitations to both design and customer.

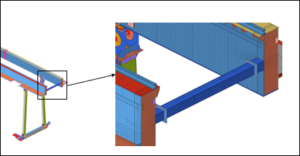

Box bracing between girders to prevent independent lateral deformation of girders as a result of Seismic analysis FEA

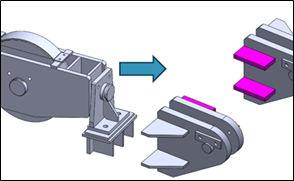

Recommended change in design from equalizer pulley to rope anchor to minimize stress below allowable limit for qualifying Nuclear Seismic Analysis

The engineering design service provided by ProSIM ensures that design failing for required operating conditions will be optimised with modifications which do not significantly alter the design impacting cost and fabrication challenges. A case study is presented where ProSIM executed seismic analysis validation for an EOT crane wherein the material of the crane exhibited higher stress for normal operating conditions more than allowable limits. ProSIM worked with the customer cum manufacturer of the crane to modify the design with available material such that it did not alter the design nor added significant additional material for increasing the strength of the design. ProSIM worked as seismic design consultants to improve the strength of the crane and reduce stress within allowable limits for both regular operating conditions added with seismic loading combinations. The design was qualified for both OBE – Operating Basis Earthquake and SSE- Safe Shutdown earthquake. ProSIM also executed analytical calculation of bolts, welds, bearings, wheels and anti-jump lugs from reaction forces obtained of simulation results and modified weld locations to ensure uniform distribution of force and eliminate stress concentration.

Due to the efforts of ProSIM, the EOT crane qualified for operation loads, OBE and SSE loading without significant changes to the design and wight and keeping in mind the material limitations of the customer. Due to the minimised changes in the design without significant use of additional material, the procurement and production schedule of the customer were executed as planned.