ASSESMENT OF DEFECT IN OFFSHORE PIPELINE

ProSIM provides offshore engineering service for oil & gas sector and has executed multiple engineering design services for oil & has organizations in India and abroad. ProSIM works as FEA engineering consultants for executing simulation based solutions to customers.

Due to significant depth of the pipe underwater, repair or replacement of the pipe was a major challenge. The customer approached ProSIM for FEA engineering services to determine if the pipe could be continued to operate in corroded condition. The scope of work for ProSIM was to evaluate the corroded section of the pipeline to withstand pressure due to oil flow and evaluate safe operating pressure of the pipe for as is condition.

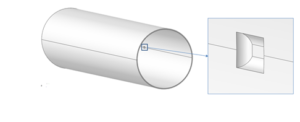

ProSIM performed analysis for various internal pressures of the oil in the pipeline to determine safe working pressure to ensure the pipe can continue functioning. The critical aspect of the project was to model the corroded region. As the exact geometry of the corroded region was not available, ProSIM created a simplified pit along the thickness taking accurate dimensions from the customer inputs. The mesh was refined for the corroded region to ensure accurate distribution of stress.

The analysis was conducted for multiple internal pressures and for each pressure case, the stress distribution was checked. From the analysis results, ProSIM recommended optimal oil flow rate to ensure the no further damage occurred. Due to the solution provided by ProSIM, the customer was able to continue using the pipeline and save costs for replacement or repair.